Slips, trips, and falls account for 12-15 percent of all Workers’ Compensation expenses, according to the U.S. Bureau of Labor Statistics. Additionally, these injuries, on average, result in 11 days away from work. Slip-and-fall injuries are preventable with the right tailored solutions. Continue reading to learn tips to eliminate downtime caused by injuries and provide the peace of mind you need to focus on other aspects of your business.

The most common risk areas for employee slips and falls and the situations that cause them include:

- Flooring: wet or greasy floors, dry floors with wood dust or powder, polished or freshly waxed floors, missing or uneven floor tiles, transition from one floor type to another

- Handrails: broken handrails, no handrails

- Ladder rungs: damaged ladder steps

- Stair treads: curled or lifted edges, loss of traction

- Stair noses: damaged or irregular steps, not enough traction (leading edge of the steps)

You can help avoid slips by following these five safety precautions:

1. Maintain Three Points of Contact

This is especially important for ladder rungs. When climbing or descending ladders, always maintain three points of contact (one hand and two feet, or two hands and one foot).

OSHA (Occupational Safety and Health Administration) considers that grasping the ladder on horizontal rungs is preferable and encourages employers to follow this practice. However, OSHA also recognizes that there may be times when it’s necessary for employees to hold the side rails.

2. Use the Trailing Hand Technique

Commonly used in offshore platforms and rigs while descending down narrow and steep ladder wells, the trailing hand technique involves trailing your strongest hand underneath the handrail behind you, turning your body slightly in order to have more stepping space, and descending the stairs in a more controlled manner.

If you slip using the trailing hand technique, your chances of falling further down the ladder are significantly reduced because your hand grip is in a stronger position to catch your fall — as opposed to a common, but unsafe, grip.

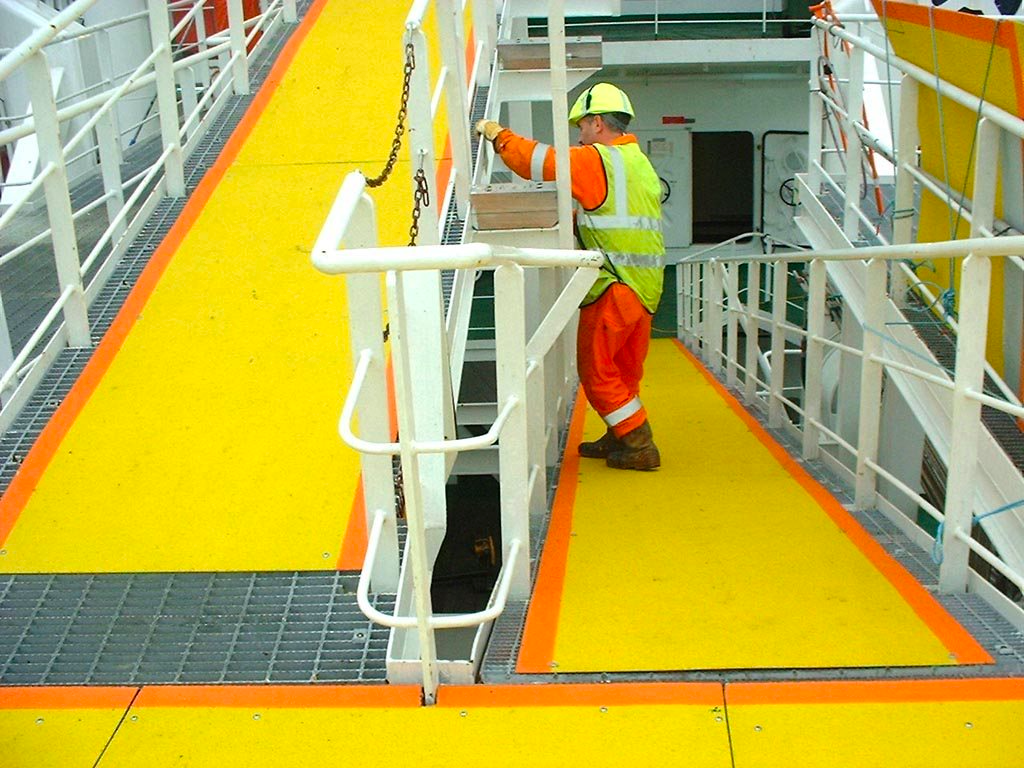

3. Use Descriptive Markings

It’s important to use descriptive markings whenever possible to communicate essential safety information and guidance. Visual cues are a great way to bring attention to people.

Reinforce Your Corporate Safety Message and PPE Requirements

Overhead safety warnings and signage can actually create a slip, trip, and fall situation when the person fails to look down while walking. Worse yet, in the event of a fire or emergency, smoke and darkness often conceal overhead signage and directional guidance.

The image or message is embedded into the cover, not just printed on the surface, so it will last for the life of the product and not wear off.

Critical Safety Messages

Commonly used phrases include:

- Use Handrail

- Use Trailing Hand Technique

- Danger Zone

- Watch Your Head

Personal Protective Equipment (PPE) Safety Symbols

Incorporating PPE safety symbols that are visible at floor level greatly increases the exposure of important safety warnings and messages. As workers and pedestrians look down while walking on hazardous areas or steps, these symbols act as a simple reminder to act and think safely. Combine with a glow-in-the-dark background for visibility after dark, during power outages, and emergency evacuations.

4. Put Anti-Slip Products on the Leading Edge of Steps

Most slips occur on the leading edge of steps. Even in adverse conditions, such as when wet, icy, or dirty, Safeguard Technology Hi-Traction® and HiGlo-Traction® anti-slip step covers provide excellent footing, far exceeding OSHA standards. Benefits of Safeguard’s Anti-Slip Step Covers:

- Combine the right base material, grit, size, and colors to cover your steps and stairs

- Wrap the leading edge and cover the proper depth for your foot traffic to eliminate slip-and-trip hazards

- Fabricated to your specifications using a durable, non-load-bearing base of FRP fiberglass, galvanized or stainless steel

Two-Tone Colors Add Visibility

Call attention to the leading edge of the step. Contrasting colors on the step edge and back of the tread provide good definition and clear visibility for added safety.

5. Reduce Wet or Slippery Surfaces

Walking surfaces account for a significant amount of slip-and-fall injuries. The most common types of surfaces where these injuries occur include:

- Parking lots

- Food preparation areas

- Floors in general

Safeguard Hi-Traction® and HiGlo-Traction® walkway and ramp covers provide non-slip flooring in any areas where slips and falls can occur. Protect your workers, customers, and business from the consequences of slip-and-fall hazards. Benefits of Safeguard’s Walkway and Ramp Covers:

- Prefabricated retrofit covers are quickly and easily installed over existing surfaces, such as concrete, wood, metal plate, and grating using mechanical fasteners or adhesive.

- Wide variety of shapes, sizes, and flexibility options

- Design solutions for every non-slip flooring need and visual preference

Tailored Anti-Slip Solutions for Any Surface

Since 1992, Safeguard has been manufacturing anti-slip covers in the U.S. to meet its’ customers’ specifications. With experience in a variety of industries and installations all over the world, we have developed an extensive body of knowledge that benefits our customers.

Our focus is 100% on providing excellent anti-slip solutions. We are not simply a warehouse with one-size-fits-all products, but an experienced innovator that has your best interests at the heart of everything we do. Our anti-slip covers are made to size, with predrilled holes exactly where needed, and the right fasteners for easy installation. You don’t have to change your parts to fit our product; we adapt to fit yours.

Slip-and-fall injuries are preventable with the right tailored solutions. Request a consultation today and let’s talk about how our anti-slip products can be designed for your needs.

James Brister is the Domestic Industrial Account Manager at Safeguard Technology, Inc., and has more than 6 years of experience providing custom anti-slip solutions. James has consulted on anti-slip projects for a multitude of industries from general industry to food processing, steel mills, petroleum, and chemical refiners, to name a few. He works directly with end-users as well as through distributors.